Precision CNC Machining of a Delrin Pocket Subassembly for the Medical Industry

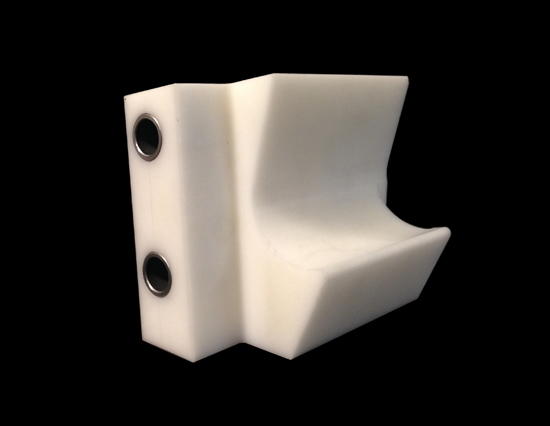

Allied Precision was commissioned by a customer in the medical industry to manufacture a custom pocket subassembly and insert. Milling and turning processes were expertly carried out on our cutting edge CNC vertical mill, along with boring and drilling operations. The subassembly was manufactured from Delrin 500 or Acetron GP, brand names for an engineering thermoplastic known for its high strength and stability. Finished dimensions for the subassembly were 5.070″ long x 3.406″ wide x 6.017″ high, with an internal diameter of 0.8530″. The insert was composed of stainless steel tubing, machined to a smooth 63 RA finish. Completed dimensions for the insert were 3.625″ long, outside diameter measuring 0.8550″, inside diameter of 0.625″, and weight of 0.117 lbs. The tight tolerances of +0.0000″/-0.0005″ were held throughout machining, along with an angular tolerance of ± 1°.

Parts were deburred and assembled, packaged and shipped to the client in New Jersey. 72 inserts and 36 subassemblies were manufactured for this project, with a turnaround time of 3-4 weeks. Allied Precision is ready to take on the challenges particular to fabrication for the medical industry, including small scale machining and effectively manipulating the different materials specific to the medical industry. We meet the highest quality standards, producing clean, burr-free, high-precision parts. We handle production from responsive prototyping all the way to full-scale heavy volume. For more details about this pocket subassembly project, or further information about our medical machining capabilities, please see the table below or contact us directly.

Precision CNC Machining of a Delrin Pocket Subassembly Project Highlights

| Product Description | Delrin Pocket Subassembly for a Medical Application |

| CNC Turning Capabilities Applied/Processes | Primary: • CNC Milling • CNC Turning • Boring • Drilling Secondary: • Deburring • Assembly |

| Equipment Used to Manufacture Part | CNC Vertical Mill |

| Overall Part Dimensions | Subassembly • Length: 5.070″ • Width: 3.406″ • Height: 6.017″ ± 0.010 • ID: Ø 0.8530″ Insert • OD: Ø 0.8550″ • ID: Ø 0.625″ • Length: 3.625″ • Weight: 0.117lbs. |

| Tightest Tolerances | 0.0000″ / – 0.0005″ Angular: ± 1° |

| Material Used | Subassembly: Delrin 500 or Acetron GP Insert: Stainless Tubing |

| Material Finish | 63 Machine Finish |

| In process testing/inspection performed | Dimensional Inspection, Visual Inspection |

| Industry for Use | Medical |

| Volume | Subassembly: 36 Insert: 72 |

| Delivery/Turnaround Time | 3-4 Weeks |

| Delivery Location | New Jersey |

| Standards Met | Customer Specifications, 2D CAD Drawing |

| Product Name | Pocket Subassembly |